-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of electrical safety and performance, maintaining the integrity of your Nh Fuse is paramount. According to the latest industry report by the International Electrotechnical Commission (IEC), improper maintenance of fuses can lead to a staggering 30% increase in electrical system failures, resulting in significant downtime and repair costs. Furthermore, a study from the National Fire Protection Association (NFPA) highlights that inadequate fuse maintenance contributes to nearly 15% of electrical fires annually. Consequently, an Essential Nh Fuse Maintenance Checklist is not just a best practice but a critical necessity for ensuring optimal performance and safety in electrical systems.

By adhering to structured maintenance protocols, equipment reliability can be enhanced while potential hazards are mitigated, ultimately leading to sustainable operational efficiency.

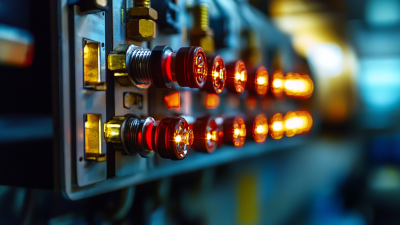

When it comes to maintaining Essential Nh fuses, understanding the key components involved in their upkeep is crucial for optimal performance. Regular inspection of the fuse holders and connections is vital to ensure that there is no corrosion or oxidation that could disrupt electrical flow. Make it a habit to conduct these inspections bi-annually to catch any issues early before they lead to significant failures.

Another critical component of NH fuse maintenance is the proper cleaning of the fuses themselves. Dust and dirt can accumulate over time, impacting both functionality and safety. Utilize a soft, dry cloth to gently wipe down the exterior of the fuses and holders. Additionally, ensure that you check for any signs of physical damage or wear. If any abnormalities are detected, replacing the fuse promptly can prevent more extensive damage down the line.

Finally, always keep a record of maintenance activities for your Essential Nh fuses. This not only helps track the lifespan and performance of each unit but also aids in planning future maintenance tasks. Incorporate a simple log to document dates, inspections, and any actions taken, which can greatly enhance the reliability of your electrical systems.

When it comes to the performance of NH fuses, identifying common issues is vital for ensuring their reliability and longevity. Research indicates that approximately 30% of fuse failures are linked to improper installation or maintenance practices. Many users overlook signs of wear, such as discoloration or corrosion, which can lead to catastrophic failures in critical applications. Regular inspections and adherence to manufacturer guidelines can help mitigate these risks and extend the fuse's operational life.

Tip: Regularly check fuse holders and connections for any signs of overheating. Ensuring that all connections are free of corrosion and securely tightened can significantly reduce failure rates. Additionally, consider conducting thermal imaging inspections to identify potential hotspots that may indicate underlying issues.

Another common issue is the use of mismatched fuses. Data from industry studies show that using the wrong type or rating of NH fuse can lead to inadequate protection and increased risk of equipment damage. Proper calibration and selection based on the application's specific demands are crucial.

Tip: Always consult the NH fuse’s datasheet and adhere to the manufacturer’s specifications when selecting a fuse for your system. This practice not only bolsters safety but also optimizes performance, ensuring all components work seamlessly together.

| Maintenance Task | Frequency | Common Issues Identified | Recommended Action |

|---|---|---|---|

| Visual Inspection | Monthly | Signs of wear, discoloration | Replace damaged fuses |

| Functional Testing | Quarterly | Intermittent failures | Test and rectify wiring |

| Connections Check | Bi-annual | Loose connections | Tighten and secure connections |

| Temperature Monitoring | Monthly | Overheating | Inspect cooling systems |

| Dust and Debris Cleaning | Monthly | Accumulation of dust | Clean thoroughly |

Regular maintenance of NH fuses is crucial for ensuring optimal performance and reliability in electrical systems. To begin, always inspect the fuses for any signs of damage or wear. Look for discoloration, cracks, or any physical deformities that may indicate a problem. A routine visual inspection can prevent catastrophic failures and costly downtime.

Regular maintenance of NH fuses is crucial for ensuring optimal performance and reliability in electrical systems. To begin, always inspect the fuses for any signs of damage or wear. Look for discoloration, cracks, or any physical deformities that may indicate a problem. A routine visual inspection can prevent catastrophic failures and costly downtime.

Next, it’s important to regularly clean the fuse contacts. Dust and debris can accumulate and interfere with the connection, leading to inefficiencies. Use a soft, lint-free cloth to gently wipe down the contacts and ensure a good connection. Additionally, consider applying a thin layer of conductive grease to minimize oxidation, enhancing conductivity.

Lastly, don’t forget to check the tightening of terminals and connections. Fluctuating current can cause connections to loosen over time, which decreases the performance of the fuses. Using a torque wrench, ensure all connections are properly tightened according to the manufacturer’s specifications. Remember, maintaining NH fuses not only increases their lifespan but also optimizes overall electrical performance.

When it comes to ensuring optimal performance of NH fuses, having the right tools and equipment at your disposal is essential. The maintenance of these critical components requires precision and care, making it crucial to be well-prepared. Start with a basic toolkit that includes insulated screwdrivers, pliers, and wire cutters. These tools will allow you to safely open fuse boxes and disconnect any faulty units without risk of electrical shock.

In addition to standard tools, consider investing in specialized equipment such as insulation resistance testers and thermal imaging cameras. Insulation resistance testers help you check the quality of your fuses and cables, ensuring they are functioning as intended. Meanwhile, thermal imaging cameras can detect hot spots and identify potential issues before they escalate into serious problems. By equipping yourself with the right tools and regularly performing maintenance checks, you can significantly extend the life of your NH fuses and maintain optimal system performance.

This bar chart represents the frequency of essential maintenance tasks performed on NH fuses over a 6-month period. Each task is crucial for ensuring optimal performance and longevity of the fuses.

Regular monitoring and care of NH fuses are critical for ensuring uninterrupted system performance and safety. The first best practice is conducting routine visual inspections to check for signs of wear or damage. Look for discoloration, cracks, or any corrosion that may indicate a failure in the fuse. Additionally, checking connections and terminals for tightness and cleanliness can prevent overheating and ensure optimal conductivity.

Another vital aspect of NH fuse maintenance is the periodic testing of their operation. Implementing electrical testing procedures, such as insulation resistance tests and functional checks, helps to identify any potential issues before they escalate. Moreover, it is advisable to keep a maintenance log to track inspections, repairs, and any changes made. By establishing a systematic approach to monitoring NH fuses, you can significantly enhance their longevity and reliability, ultimately contributing to the overall efficiency of the electrical system.