-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

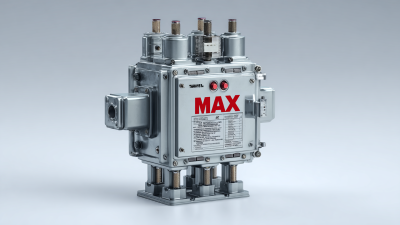

In today's increasingly electrified world, optimizing electrical systems for efficiency has never been more critical. According to a recent report by the International Energy Agency (IEA), global electricity consumption is projected to soar by 60% by 2040, making the need for advanced technologies and components, such as Pt Fuses, a top priority for engineers and facility managers. Pt Fuses serve a dual purpose: they protect electrical circuits from overloads while simultaneously ensuring minimal energy loss during operation. A study by the Electric Power Research Institute (EPRI) revealed that implementing high-performance fuses can enhance system reliability by up to 30%, thereby reducing downtime and maintenance costs. As industries strive to balance efficiency with safety, understanding the role and advantages of Pt Fuses within electrical systems is essential for achieving optimal performance and sustainability.

In today's rapidly evolving electrical landscape, the role of protection devices such as PT fuses cannot be overstated. These devices are essential in enhancing electrical efficiency by safeguarding systems against overloads and faults. According to a report by the International Electrotechnical Commission (IEC), improperly protected electrical systems can lead to up to 30% of energy loss due to equipment failures and inefficiencies. By integrating PT fuses, operators can effectively mitigate these risks, ensuring that electrical operations remain within optimal limits.

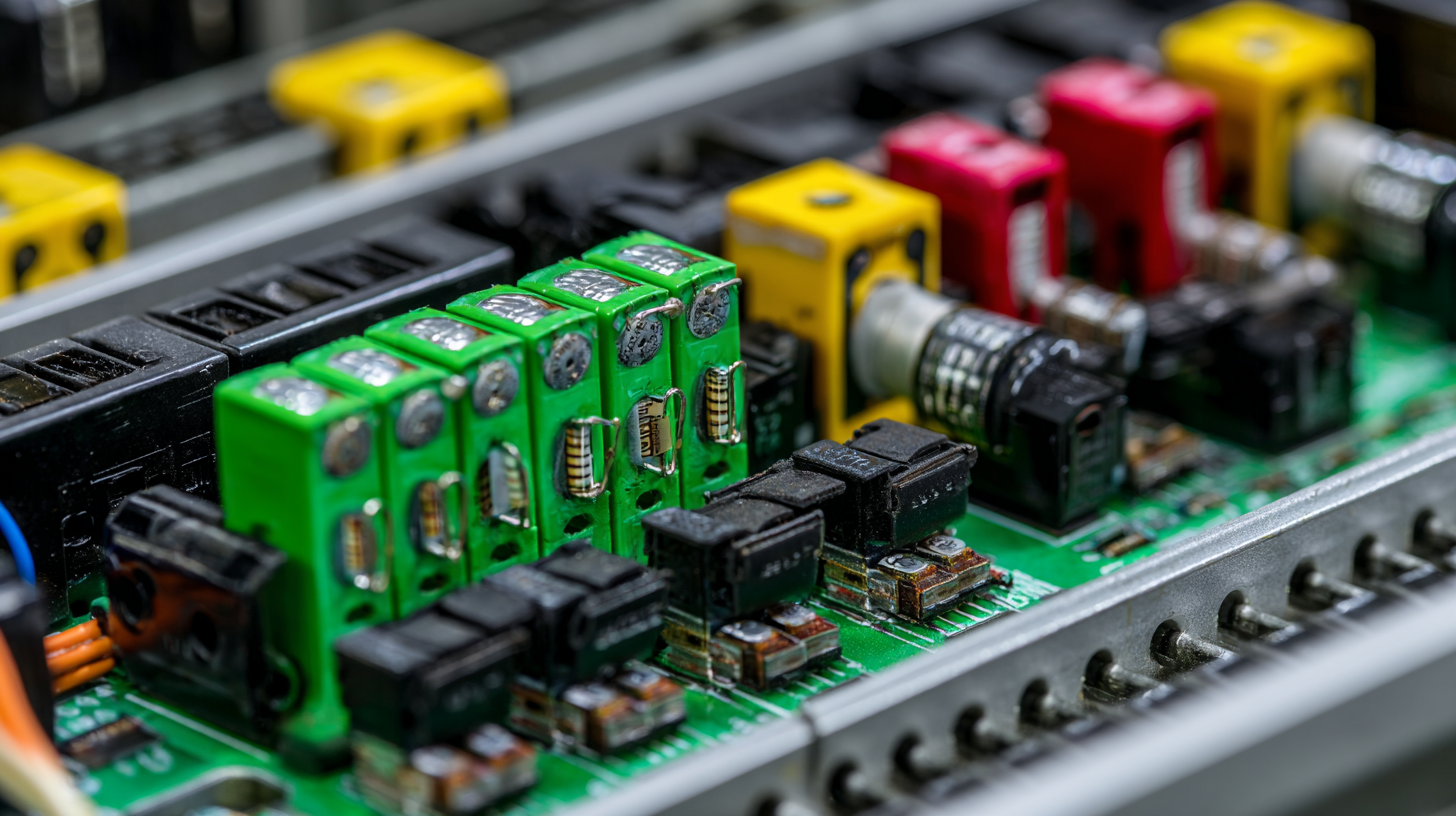

Moreover, PT fuses offer the added benefit of seamless integration with modern smart grid technologies. A study published by the Institute of Electrical and Electronics Engineers (IEEE) indicates that the implementation of intelligent fuses can improve the reliability of electrical systems by 25-30%. By providing precise monitoring and rapid response during fault conditions, PT fuses play a crucial role in not only maintaining operational efficiency but also in extending the lifespan of electrical components. As industries continue to pursue greater energy standards, the significance of using PT fuses in electrical systems becomes increasingly evident.

This chart represents the efficiency improvement in electrical systems when utilizing PT fuses across different power levels.

When selecting PT fuses for your electrical systems, several key factors come into play that can greatly impact efficiency and safety. First, consider the voltage and current ratings required for your specific application. According to the International Electrotechnical Commission (IEC), using fuses that cater to precise current ratings can prevent unnecessary blowouts and enhance system reliability. For example, a mismatch in current ratings can lead to excessive energy losses and downtime, which are detrimental to overall performance.

Another essential aspect to evaluate is the fuse's interrupting capacity. According to a report by the Electrical Safety Foundation International (ESFI), selecting fuses with appropriate interrupting ratings can safeguard against catastrophic failures. This is crucial in systems where short circuits may occur, as high interrupting capacity fuses can swiftly cut off the flow, mitigating potential damage.

Tip: Always refer to manufacturer specifications and industry standards when choosing your PT fuses to ensure compatibility.

Additionally, consider environmental factors such as temperature and humidity, which can influence fuse performance. A study by the National Electrical Manufacturers Association (NEMA) highlights that operating PT fuses in extreme conditions can lead to reduced lifespan and reliability. Therefore, it's advisable to choose fuses designed for specific environmental limits to enhance durability.

Tip: Implement regular maintenance checks to monitor the condition of PT fuses in your systems and replace them proactively to avoid unexpected failures.

When designing electrical systems, understanding the impact of Pt fuse ratings on performance and safety is crucial. The correct fuse rating can significantly enhance the efficiency of electrical systems. According to the IEC 60269 standard, using fuses with ratings that match the load requirements can prevent unnecessary outages and equipment failures. For example, a mismatch in ratings can lead to overheating and possible fire hazards, while properly rated fuses contribute to a reliable system by minimizing noise and energy loss.

Tips for selecting the right Pt fuse rating include assessing the system’s maximum load, as well as its inrush currents, which can be substantially higher than operating currents. It’s advisable to consult performance curves, which help in selecting a fuse that provides adequate protection without nuisance tripping. Additionally, keeping in mind environmental factors such as temperature and humidity is essential, as these can affect fuse performance and longevity.

Moreover, regular maintenance and testing of the Pt fuses are vital for ensuring long-term safety and efficiency. According to a study by the National Fire Protection Association, over 30% of electrical fires are tied to malfunctioning systems, including issues related to improper fuse ratings. By implementing a routine check on fuse conditions and load assessments, systems can not only operate safely but can also achieve optimal performance levels.

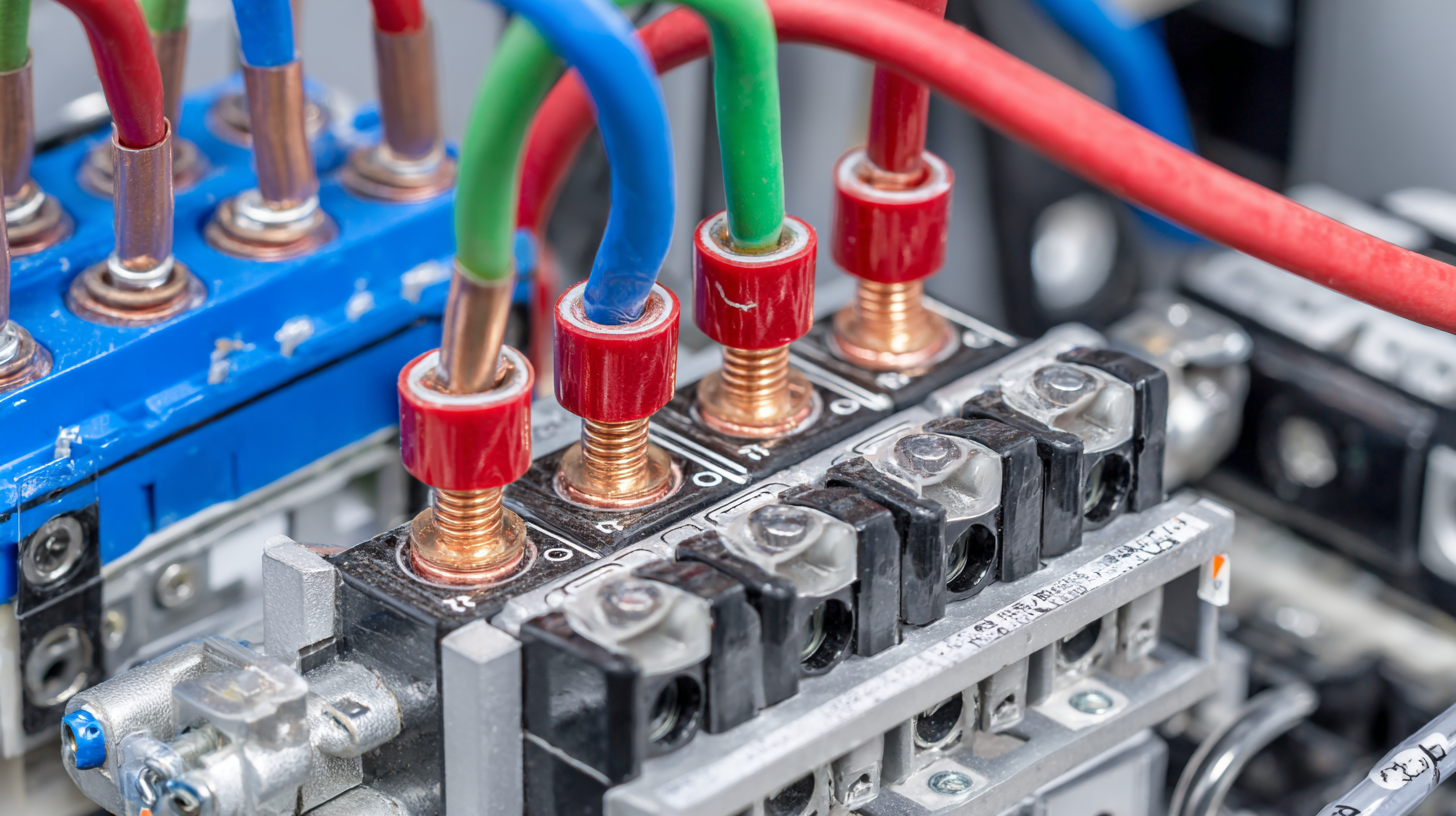

Maintaining and monitoring Pt fuses is crucial for ensuring optimal performance in electrical systems. According to the International Electrotechnical Commission (IEC), regular maintenance can reduce the risk of equipment failure by up to 30%. This proactive approach involves routine inspections to check for signs of wear or damage and ensuring that fuses are functioning within their specified ratings. Additionally, implementing a predictive maintenance program, which relies on data analysis and condition monitoring tools, can significantly enhance reliability. Reports indicate that organizations adopting such practices experience a 25% increase in overall system efficiency.

Monitoring Pt fuses also entails keeping track of operational parameters, such as temperature and load conditions. Data from the Association of Electrical and Electronics Engineers (IEEE) suggests that real-time monitoring can help identify potential issues before they escalate into serious problems. By utilizing advanced monitoring technologies, such as infrared thermography and smart fuse technology, systems can alert operators to discrepancies immediately. This level of vigilance not only maximizes efficiency but also prolongs the lifespan of electrical components, thus reducing replacement costs and improving safety standards across operations.

| Dimension | Value | Notes |

|---|---|---|

| Rated Current (A) | 100 | Standard rating for most applications |

| Voltage Rating (kV) | 15 | Common for medium voltage systems |

| Typical Lifespan (years) | 10 | Depends on usage and environment |

| Maintenance Frequency (months) | 6 | Regular inspections recommended |

| Monitoring Technology | Smart Sensors | Real-time monitoring for efficiency |

| Common Failure Mode | Overcurrent | Leads to fuse blowing |

Recent studies have highlighted the significant benefits of implementing Pt fuses in various industrial applications. For instance, a report by the Electric Power Research Institute (EPRI) indicates that industries using Pt fuses have experienced a reduction in downtime by up to 30%. This is particularly vital for manufacturing processes where consistent power supply is crucial. Take the automotive sector, where an automotive manufacturer reported that the introduction of Pt fuses in their electrical systems led to a 25% increase in efficiency, allowing for improved output and reduced operational costs.

Moreover, the integration of Pt fuses in renewable energy systems is becoming increasingly prevalent. According to a recent analysis by Navigant Research, the use of Pt fuses in solar inverter applications has enhanced system reliability, resulting in less than 1% failure rate compared to traditional fuses. This reliability translates into higher energy production rates and prolonged equipment lifespan. One solar farm in California observed a 15% increase in energy output post-implementation, showcasing how Pt fuses can play a crucial role in optimizing electrical systems across diverse industries.