-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

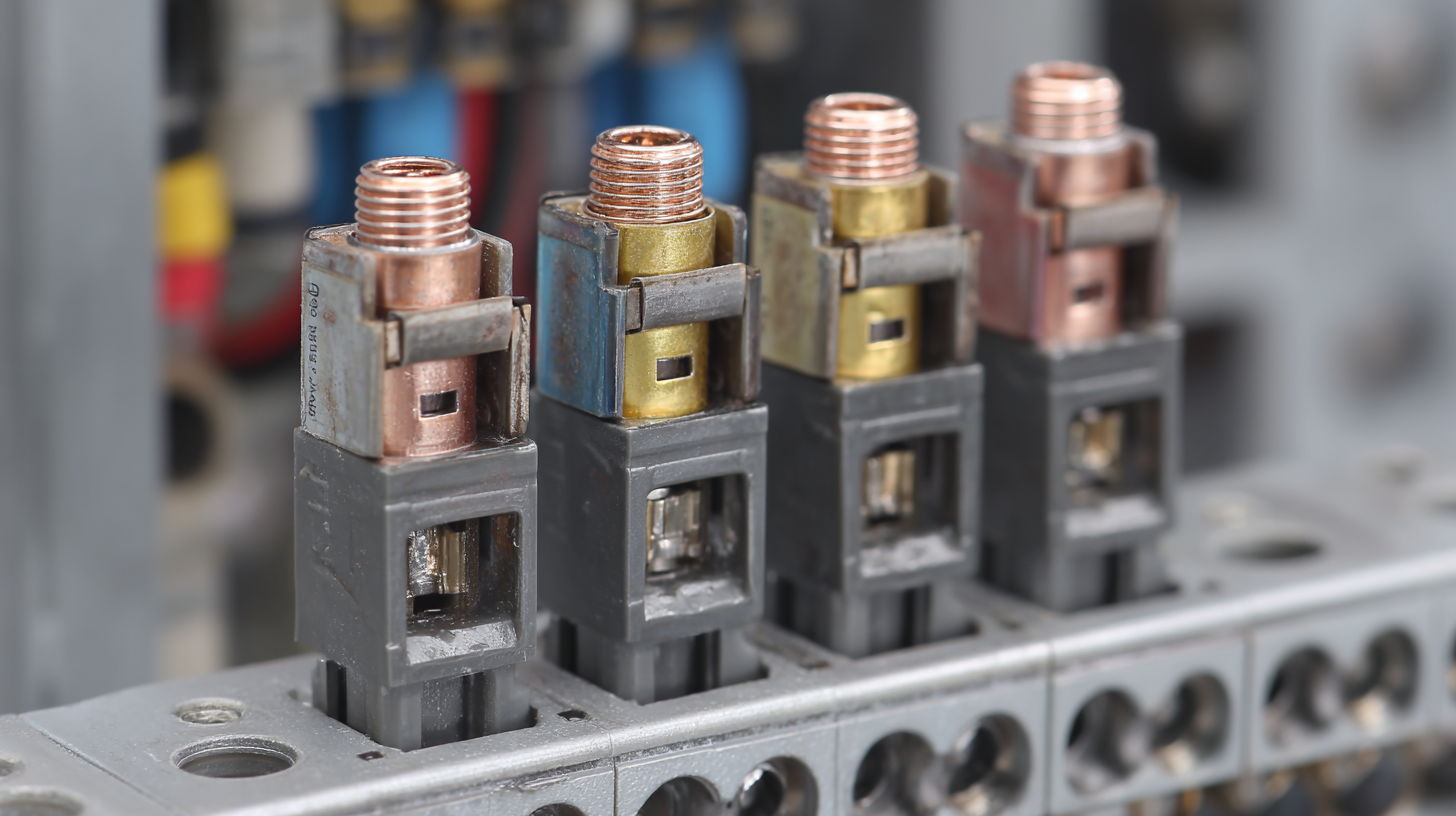

In today’s global sourcing landscape, selecting the right components is crucial for ensuring efficiency and reliability, particularly in the realm of electrical safety. The demand for J Slotted Fuse has surged, with recent industry reports indicating a compound annual growth rate (CAGR) of 5.8% in the global fuse market from 2021 to 2028. This trend underscores the increasing necessity for robust safety devices in various applications, including automotive, industrial, and consumer electronics. As companies expand their operations internationally, understanding the specifications and applications of J Slotted Fuse becomes vital. This type of fuse not only enhances system protection but also contributes to overall operational performance. Therefore, choosing the appropriate J Slotted Fuse is essential for businesses aiming to optimize their sourcing strategies while adhering to safety and compliance standards in a rapidly evolving market.

When selecting the right J Slotted fuse for your global sourcing needs, it is essential to first understand the fundamentals of J Slotted fuses and their diverse applications. J Slotted fuses are critical components in electrical systems, designed to provide overload and short-circuit protection. They come in various ratings and sizes, making them suitable for different industries, from automotive to renewable energy. Understanding their specifications can significantly impact the reliability and performance of your electrical equipment.

The applications of J Slotted fuses extend beyond mere protection; they are integral to enhancing system efficiency. For instance, advancements in technology signify the importance of integrating these fuses within modern infrastructures. Recent innovations in decentralized finance (DeFi) underline how vital robust electrical components are for powering complex systems that demand reliability, such as those seen in financial platforms. Additionally, with the rise of open-source solutions in the integration process, as demonstrated with new service design technologies, the role of J Slotted fuses in maintaining system integrity cannot be overstated. Proper knowledge and selection will ensure optimal performance and safety in all applications.

When selecting J slotted fuses for your projects, understanding key factors is crucial to ensuring compatibility and efficiency. One of the primary considerations is the fuse's voltage and current ratings. According to industry data from the International Electrotechnical Commission, approximately 70% of electrical failures are linked to the incorrect selection of these ratings. Therefore, cross-referencing the operational requirements of your application with the specifications of the fuse can minimize the risk of overload and prevent catastrophic failures.

Another vital aspect is the physical dimensions and mounting style of the J slotted fuse. Different projects may require varying sizes to fit into specific layouts, and hence, adhering to standardized measurements is essential. Research from the Global Electronics Association highlights that nearly 60% of sourcing issues stem from incompatibility in physical attributes. Pay special attention to these details to ensure that your electrical design can accommodate the fuses without compromising performance.

**Tip:** Always consider the environmental conditions in which the fuse will operate. High temperatures or humidity levels can affect performance. Use J slotted fuses rated for extreme conditions if your project may encounter such environments.

**Tip:** It is prudent to consult with suppliers and review data sheets before finalizing your selection. This practice can help uncover any additional nuances in performance characteristics that may impact your project’s outcome.

When it comes to selecting the right J Slotted Fuse for your global sourcing needs, understanding the different types available is crucial. Each type has its own set of advantages and disadvantages which can significantly impact your operations. For instance, standard J Slotted Fuses offer reliability and ease of installation, making them a popular choice for many applications. However, they may not always deliver the optimal performance in high-stress environments.

On the other hand, specialized J Slotted Fuses, like those designed for extreme temperature ranges, provide better protection under specific conditions. Their enhanced durability can justify the higher cost if your application demands it. Consider the operational environment and electrical requirements carefully before making a decision to ensure you choose the fuse that aligns best with your needs.

**Tip:** Always verify the certification and compliance of the fuses with relevant safety standards, especially when sourcing globally. Another important aspect is to consult with manufacturers or suppliers to understand the nuances and suitability of each fuse type for your specific applications. This proactive approach can save time and resources in the long run.

| Fuse Type | Pros | Cons | Best Applications |

|---|---|---|---|

| Standard J Slotted Fuse | Cost-effective, widely available | Limited to specific voltage ratings | General purpose electrical circuits |

| High-Rated J Slotted Fuse | Handles higher currents, more robust | Higher cost, bulkier size | Industrial machinery, heavy equipment |

| Slow-Blow J Slotted Fuse | Durable, withstands temporary overloads | Slower response time in fault conditions | Motor circuits, transformer protection |

| Fast-Acting J Slotted Fuse | Quick response to faults, protects sensitive equipment | Can blow under normal startup conditions | Electronic circuits, sensitive devices |

When it comes to global sourcing of J Slotted fuses, developing efficient strategies is paramount for complying with various regulatory requirements and meeting quality standards across different markets. First, it's crucial to understand the specifications and certifications required in your target regions. By establishing clear communication with suppliers about these specifications, you can ensure that the products you source meet both regulatory compliance and customer expectations, minimizing the risk of delays or returns.

Another effective strategy involves leveraging technology to streamline the procurement process. Utilizing advanced supply chain management software can help in tracking supplier performance, analyzing pricing trends, and forecasting demand. This data-driven approach allows businesses to make informed decisions, negotiate better terms, and ultimately achieve cost savings. Additionally, maintaining strong relationships with diverse suppliers across different geographical locations can provide flexibility and resilience, ensuring a steady supply of J Slotted fuses, even amidst changing market dynamics.

Ensuring compliance with quality standards is crucial for organizations sourcing J slotted fuses globally. With the introduction of new Quality Control Orders (QCOs) by governments across various sectors, including industrial materials and electronics, businesses must remain vigilant. Compliance not only guarantees product quality but also fosters trust with clients. Reports indicate that organizations adhering to stringent quality standards can see a 20% improvement in client retention and satisfaction, making it an essential practice for sourcing operations.

Tips for Quality Compliance:

By focusing on these aspects, organizations can effectively navigate the complexities of global sourcing while ensuring the quality and compliance of their products.